WASTE MANAGEMENT

MAKING THE MOST OF MANURE – DT CENTRIFUGE

Dairy Specialists, in partnership with Centrisys, introduces the DT Model Decanter Centrifuge—a masterfully crafted solution, engineered to address the shifting challenges of manure management in the dairy and livestock industries. Throughout our 18-year collaboration, Dairy Specialists and Centrisys have continuously honed the unique application of centrifuge technology within the dairy sector. As producers expand operations and herd sizes, our solution is precisely tailoredto aid farmers in meeting strict environmental standards while optimizing operational efficiency and driving profitability.

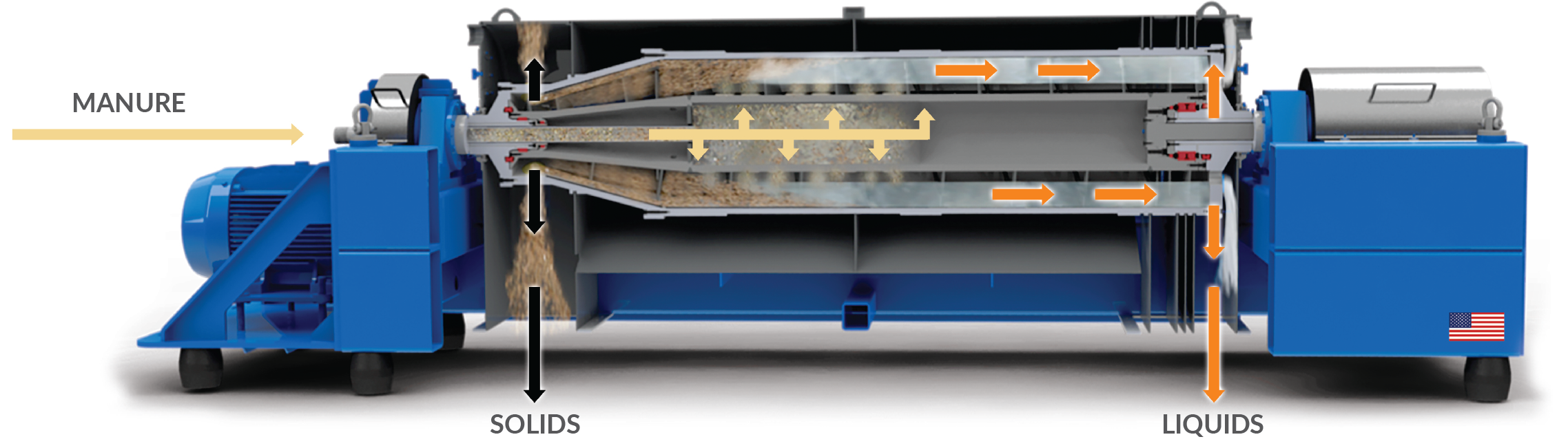

DT Model Decanter Centrifuge

Designed and built in the U.S.A., the Centrisys decanter centrifuge efficiently removes suspended solids from manure using up to 3,000x gravity, dewatering without chemicals and leaving less than 1% solids in the effluent.

Key Advantages of the DT Centrifuge Technology

- Decrease Nitrogen by Up to 50%

- Achieve Chemical-Free Phosphorus Removal

- Lower Total Nutrients by Up to 60%

- Superior Liquid Clarification

- Reduce the Frequency of Lagoon Dredging & Irrigation Clogs

For Digestor Equipped Dairies:

- Manage Digestate Without Polymers, Reducing Total Suspended Solids (TSS) Overload of Ag Land

DS Comprehensive Support Network

- Dairy Specialists (DS) & sister company, The Dairy Solutions Group (TDSG) trained service staff

- Stocked Parts Inventory

- DS Rotating Assemble Change Out Program

- Service centers in CA (Turlock, Tulare), AZ, CO, ID, OR, WA and KS

- Centrisys repair factory in Stockton, CA

- Custom lab testing available with Centrisys

Left Side: Secondary separation Centrisys Centrifuge 200GPM.

Right Side: Primary separation 2-stage slope screen roller press 1,200GPM.

Primary/Secondary System (GEA Slope Screen with roller press & Centrisys Centrifuge):

- Designed to handle large volumes of flush water

- Low horsepower / reasonable maintenance costs

- Capable of processing 1200 gpm or 1.728 MGD

- Captures 25% +/- solids to moisture from the roller press

- Improved solids / nutrient capture rate

- Gives more resident time of the manure stream in the Centrifuge (greater settling / capturing solids)

- More efficient than any other brand of Centrifuge on a dairy

Centrisys – Centrifuge System

Dairy Specialists installed the first Centrisys Centrifuge system for the dairy industry in 2007, still running at 400 gpm 24/7/365. Since installation we continue to maintain the system and work to refine the solid separation process in partnership with Centrisys. With this system you can be sure you will have the very best manure dewatering system available in the industry.

Custom design and solutions

main office

Dairy Specialists, LLC

3309 Empire Street

Evans, CO 80620

MAIN

970-330-1870

24-HOUR SERVICE

970-330-1870

FAX

970-330-1872

Syracuse, KS Location

409 E. Highway 50

Syracuse, KS 67878

MAIN

620-384-6262

Tillamook, OR Location

2 Stillwell Ave

Tillamook, OR 97141

Independence, OR Location

605 S 3rd St

Independence, OR 97351

MAIN / FAX

503-354-5359

24-HOUR SERVICE

503-812-4452

CONNECT

Hours: 8:00AM – 5:00PM

Email: info@dairyspecialists.com

main office

Dairy Specialists, LLC

3309 Empire Street

Evans, CO 80620

MAIN

970-330-1870

24-HOUR SERVICE

970-330-1870

FAX

970-330-1872

-

Syracuse, KS Location

409 E. Highway 50

Syracuse, KS 67878

MAIN

620-384-6262

-

Tillamook, OR Location

2 Stillwell Ave

Tillamook, OR 97141

McMinnville, OR Location

1430 NE Alpha Drive

McMinnville, OR 97128

MAIN / FAX

503-354-5359

24-HOUR SERVICE

503-812-4452

CONNECT

Hours: 8:00AM – 5:00PM

Email: info@dairyspecialists.com